Product Description

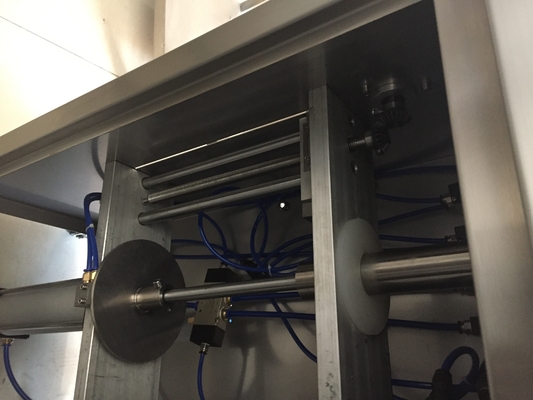

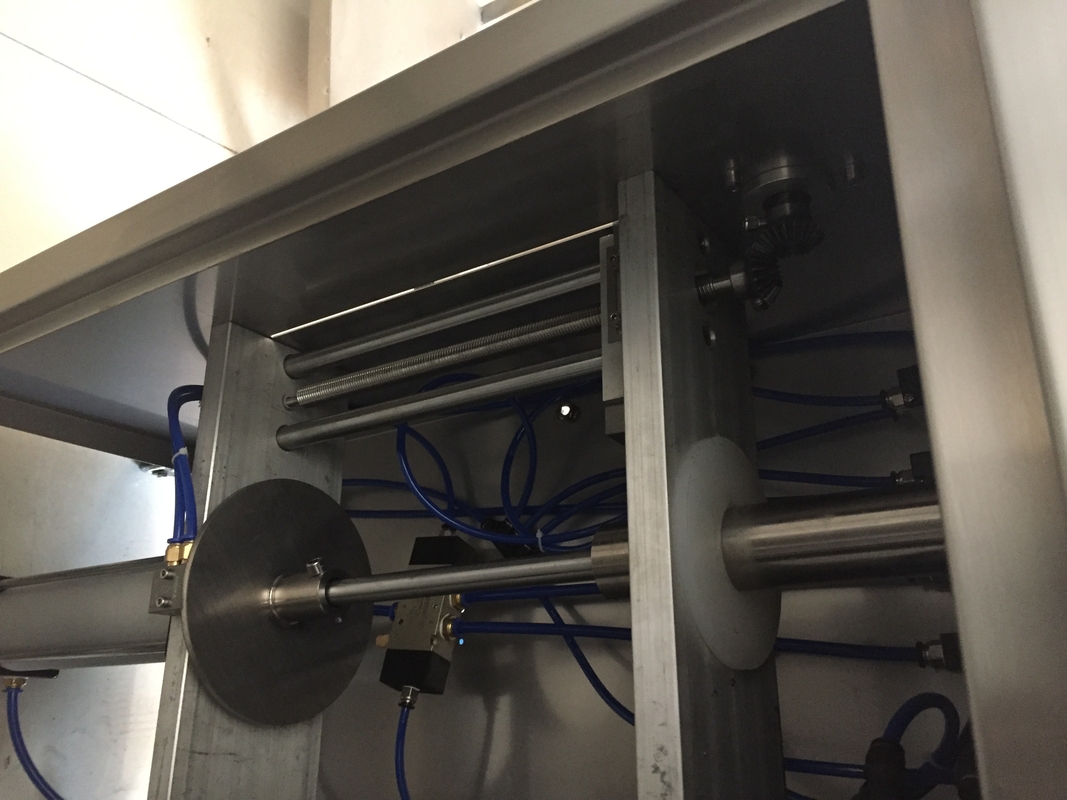

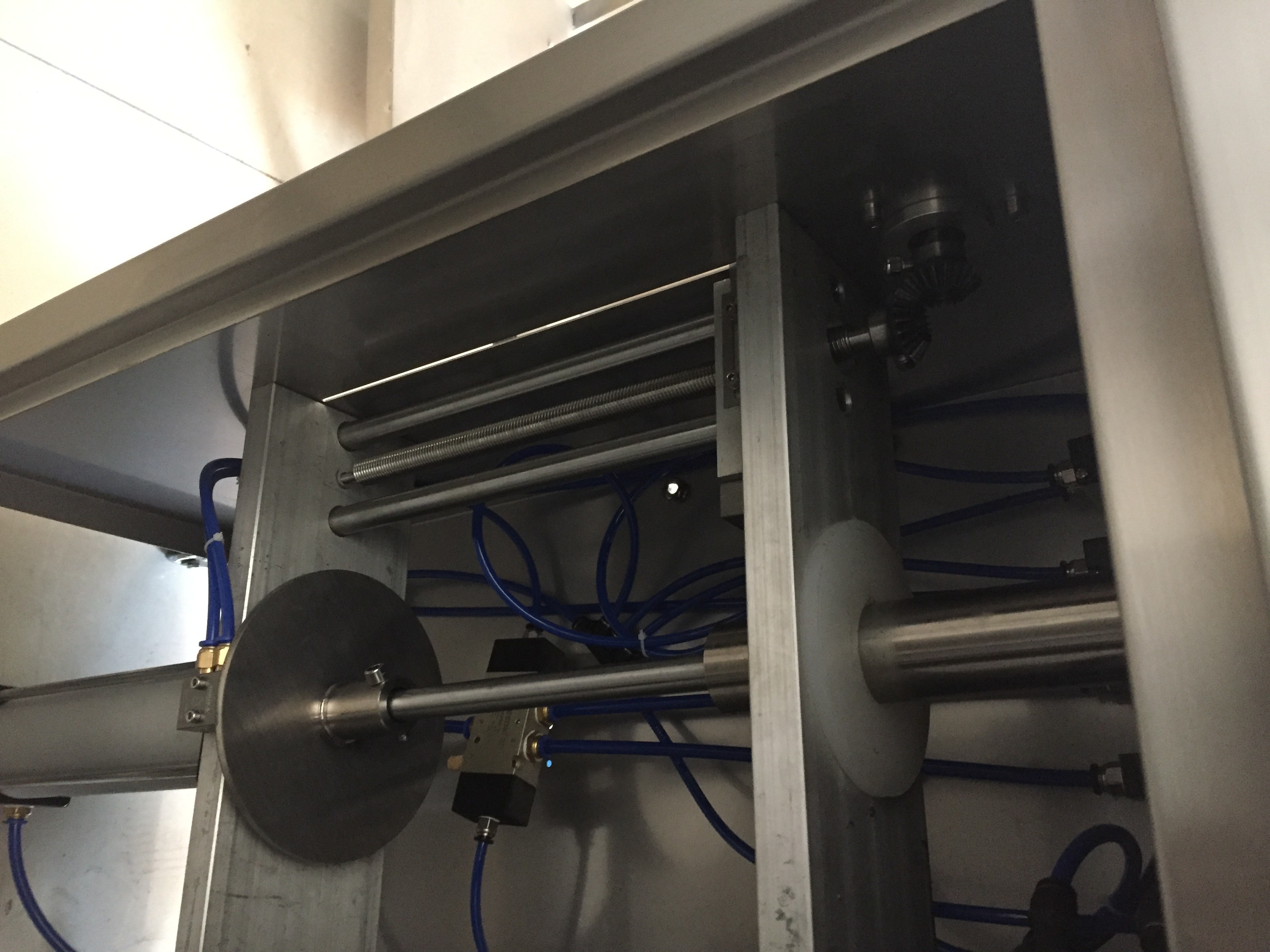

Cosmetic Filling Machine Distributor/Accurate Automatic Packaging System , Cream / Paste Auto Packing Machine

Fault resolution

The piston cannot move backwards and forwards:

Check that the air pressure is on

Check that the air pressure valve is open

Check whether the air source switch is on and whether the air control safety valve is pressed open

Check whether the air pressure reached 4-5㎏/ C ㎡

Check that the check valve is installed correctly

Check whether the piston head O ring is viscous and the piston is blocked

Check whether the front and rear air control switches on the cylinder are damaged

Filling can not reach the accuracy:

For high viscosity product speed should be slow, check whether the sealing parts leakage;

Check if there is enough material in your hopper or feed bucket;

Check whether the material cylinder is loose and the program control switch is loose;

Material overflow from the cylinder:

Check and replace the piston head O ring;

If your material is particularly thin, use two O rings;

Use only two O rings if necessary.

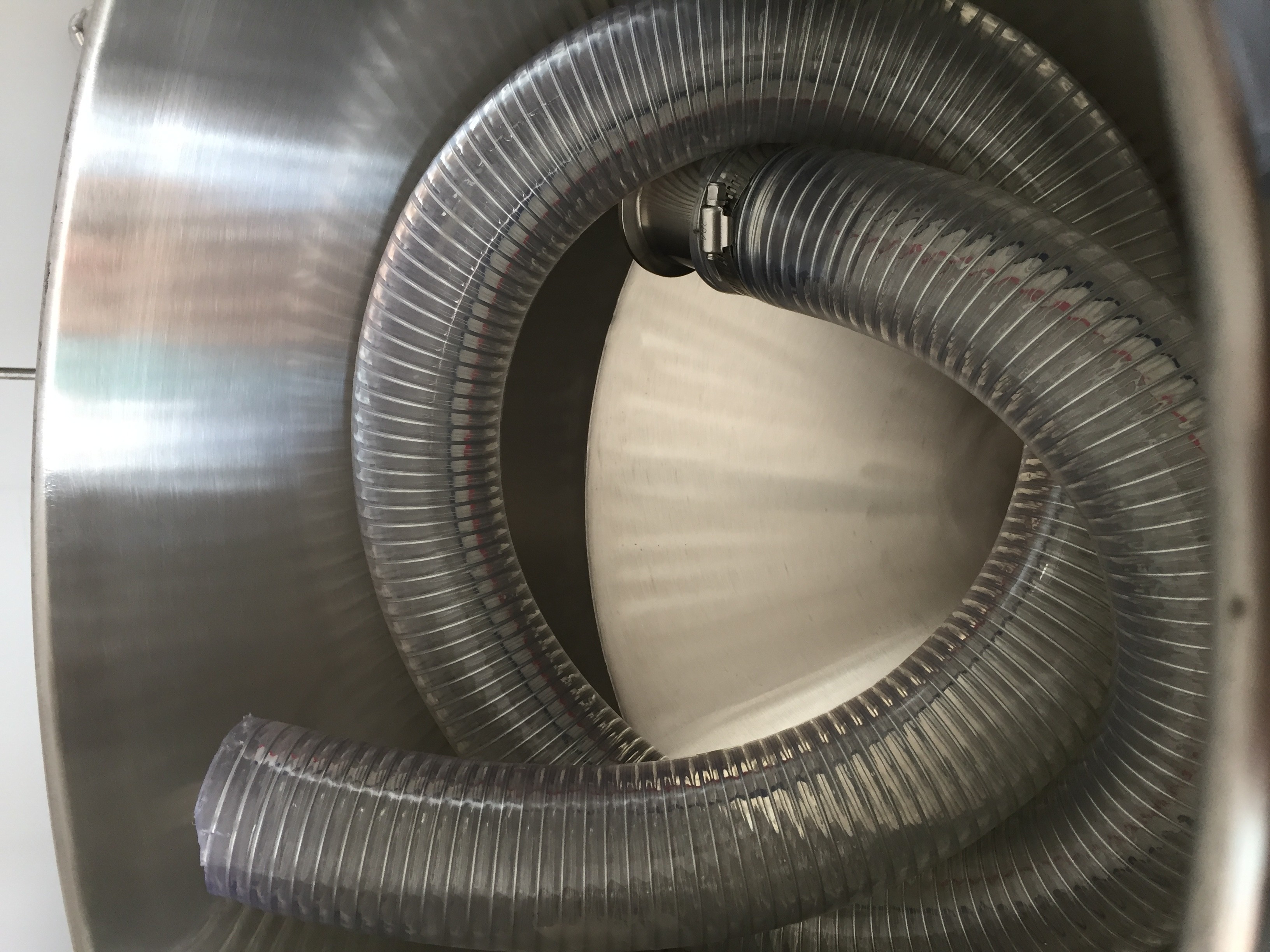

Unable to absorb material:

Check whether the valve is properly installed and fastened;

Check whether the feed pipe is properly installed and fastened;

Confirm that the suction pipe is not jacked on the bottom of the barrel;

The material suddenly overflowed the bottle mouth:

Check whether the programmed switch is damaged;

Whether the filling head is aligned with the bottle mouth;

Check whether the throttle valve of the cylinder is properly adjusted, causing too fast discharging.

The semi-automatic piston filling machine produced by our company has been redesigned on the basis of reference to similar foreign products and some additional functions have been added. It makes the operation, precision error, load adjustment, equipment cleaning, maintenance and other aspects more simple and convenient.

On this basis, the pneumatic filling machine adopts pneumatic components to replace the electrical control circuit, so it is especially suitable for use in the environment with explosion-proof requirements.

The type of filling machine produced by the company is determined according to the maximum filling volume required by the user.

The specific model is:

TVFA1- 6

|

(5-60ml)

|

TVFA1-12

|

(15-120ml)

|

TVFA1-25

|

(60-250ml)

|

TVFA1-50

|

(120-500ml)

|

TVFA1-100

|

(100-1000ml)

|

TVFA1-250

|

(500-2500 ml)

|

TVFA1-500

|

(500-5000 ml)

|

AUTOMATIC CREAM & PASTE FILLING MACHINE

Automatic Cream & Paste Filling Machine,quick and accurate filling possible. Suitable for such as Bottling filling for sauce cream,liquid, oil cosmetic etc. Widely apply to manufacturer of oil, honey, oil, shampoo, sauce, chemicals, medicine, pharmaceutical etc, or any paste and liquid type industrial.

Qihang according to wishes designed to meet both the technical requirements and investment plan to match the best solution. And relying on their own understanding of the technology industry and the cosmetics industry professional self-control team, committed to the professional digital solutions to provide the best quality customer service.

PROJECT CASES:

Manage ltem: vacuum homogenizing emulsifiers, high shear liquid detergent mixers, reverse osmosis ion water devices, various water injection, liquid and ointment semi-automatic and automatic filling production lines, round and flat bottles automatic and semi-automatic labeling machines, perfume whole-set production lines, laboratory equipment, flow lines, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!